- Car designs are thrashed out virtually before being uploaded to a program which simulates airflow around them.

- Other software systems stress test each nut and bolt in different weather conditions to ensure the design will hold up over a full season.

Motor racing hasn't always been a display of precision engineering.

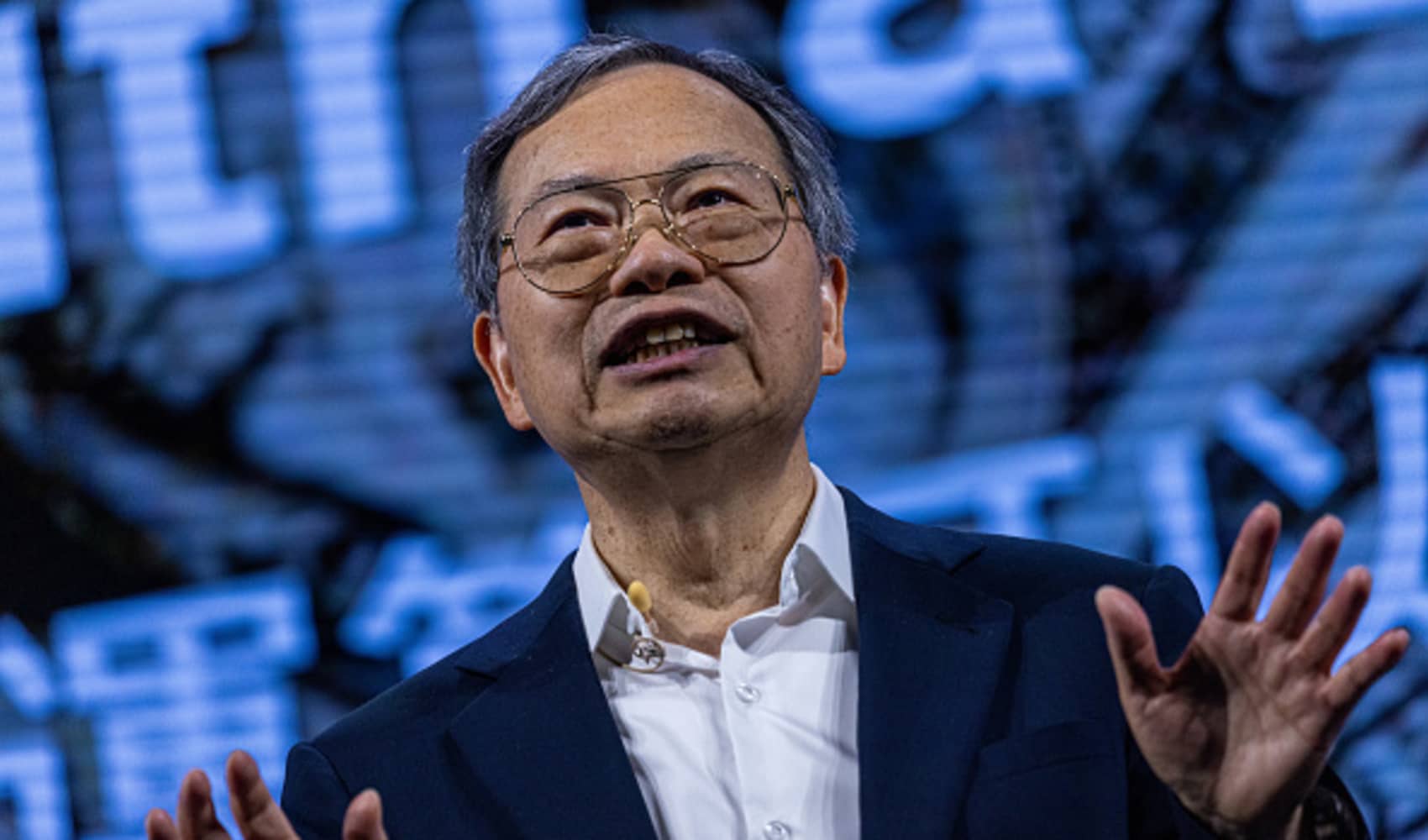

"Twenty years ago you built the car and found a wishbone would be going through a piece of body work; drill that out and you find the axles are in the wrong place," Williams CEO James Vowles told CNBC's "Inside Track."

Get top local stories in San Diego delivered to you every morning. Sign up for NBC San Diego's News Headlines newsletter.

Yet with 24 races packed into the modern Formula One season and a limit on how much money you can spend competing, even minor mistakes can cost titles. To avoid them, teams are relying more heavily on digital tools. Car designs are thrashed out virtually before being uploaded to a program which simulates airflow around them. Meanwhile, other software systems stress test each nut and bolt in different weather conditions to ensure the design will hold up over a full season.

"Once we think we found a design that is performant, we build a 60% version and put it in a wind tunnel," Dan Keyworth, director of business technology at McLaren, told CNBC, adding that these prototypes are fitted with hundreds of sensors that allow software engineers to simulate the car's performance in different scenarios.

Unlike a fully built car, which couldn't feasibly be flown around the world for testing, these "digital twins" allow teams to model conditions the real car will need to perform in. It also allows them to adapt the cars to each driver. "There's a lot of things that you analyze or work on before you get to the racetrack, including spending time on the simulator," said Red Bull driver Max Verstappen. "You really try and optimize the car as soon as it hits the ground."

Money Report

Doing this with a digital twin allows teams to develop strategies for different circuits. Cars designed for fast tracks like Britain's Silverstone will lack the grip and downforce needed for somewhere like Monaco where drivers will need to use the full width of the track. With 24 races on the schedule and only a handful of days in between, forecasting track performance is critical to ensuring engineers are ready to make any necessary changes.

It also allows them to adapt strategies in real-time. While teams are allowed up to 60 operational staff at the track on race days, each is communicating with analysts back at headquarters. "We have direct links of data being passed real time from the racetrack back to our mission control room," said Ben Waterhouse, Red Bull's head of performance engineering. "Everyone there will be looking at their computer and providing feedback to the racetrack engineers with recommendations that can be actioned onto the race car."

These recommendations have become more accurate as teams have gone from stopwatches and handheld engine thermometers to in-car sensors that produce 1.1 million data points per second. "This is where AI and Machine Learning is very powerful because it is able to react far quicker than human beings," said Vowles. "However, there are areas where human heuristics are required, for example if there's been a crash, a human can look at that very quickly and determine whether there will be a red flag."

With the cost-cap limiting budgets to $135 million per year, automating repetitive tasks is crucial to ensuring teams are using their resources efficiently. Engineers have already handed the job of forecasting inventory costs and organizing transport over to machines, while analysts are using pattern recognition algorithms to determine when other teams are likely to pit during a race.

When it works well, regulation can drive teams to find new ways to use these technologies.

"It used to be that we could afford to take quite a major risk in terms of — are we going to get a performance benefit from this?" said Waterhouse. "But what the latest regulations have done is forced us to change how we look at innovation; to be very mindful of costs and focus much more on efficiency."

As AI and other technologies improve, finding ways to deploy them will increasingly determine F1 championships. Tech companies have rushed in to lend teams a hand, signing a slew of new sponsorship deals in the last two years alone. Unlike the tobacco companies that sponsored previous generations of F1 teams, technology firms have skin in the game. The cloud computing giant Oracle, is not only paying a reported $300 million to be Red Bull's title sponsor, but also giving them access to cloud infrastructure and AI expertise. Google's partnership with McLaren is built on similar principles, providing technology and expertise in exchange for a global platform where they can test it against their business competitors.

This is a new era, not just for F1, but for sport. The greatest competitors are no longer the best athletes or superior strategists, but the most innovative.